Oh, and that robot thing…

Looking back today I just realized that I forgot to post two things in my last update. Firstly is a quick mention of this oddity, fit for my own personal AVR Museum:

Some XMEGA samples, in DIP package! Don’t get your hopes up; these were part of a very limited test run, performed at the behest of a “large” Atmel customer. I sort of, kind of won these three in a short AVRFreaks “competition”, which was really just a request for community feedback on a new ASF service. Never one to pass up something odd like myself, they now sit on my desk until I can think of a place to put them. I really do have a semi-Atmel curio museum now, with my AVRMan Action Figure, the new DIP XMEGAs, my AT90S8515 silicon wafer, beta versions of several boards and a few unreleased and cancelled boards.

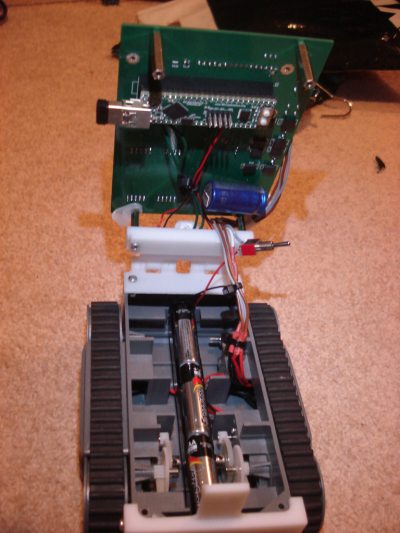

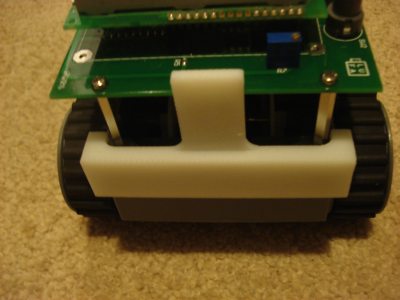

Now for the other thing – my final year project progress. I mentioned a little while back that I finished the construction, but never posted the pictures. Sorry for the poor light levels:

While the prototype here is running off 6 AA batteries, proper Li-On batteries are on order for the finished robot, to give it a longer run time than the current 30 or so odd minutes. Note the upside-down Micropendous board with the Bluetooth adapter acting as the brains of the robot, and the return of the patented “Giant Novelty Cap”. The big capacitor isn’t really needed anymore, but I decided to keep it tucked away just for the look of the thing. Who said engineering and aesthetics don’t mix?

The white plastic bits at the front and back of the robot were actually printed out on our University’s new (cheap) 3D printer. This forms a quite elegant hinge-and-clip mechanism designed by my supervisor Robert Ross to give the robot mechanical stability and to hold the front headlights and speaker/buzzer firmly in place.

I’m still heavily working on the code, but I have enough of the stack and robot working to be able to drive it around with my mobile phone and a PS3 controller:

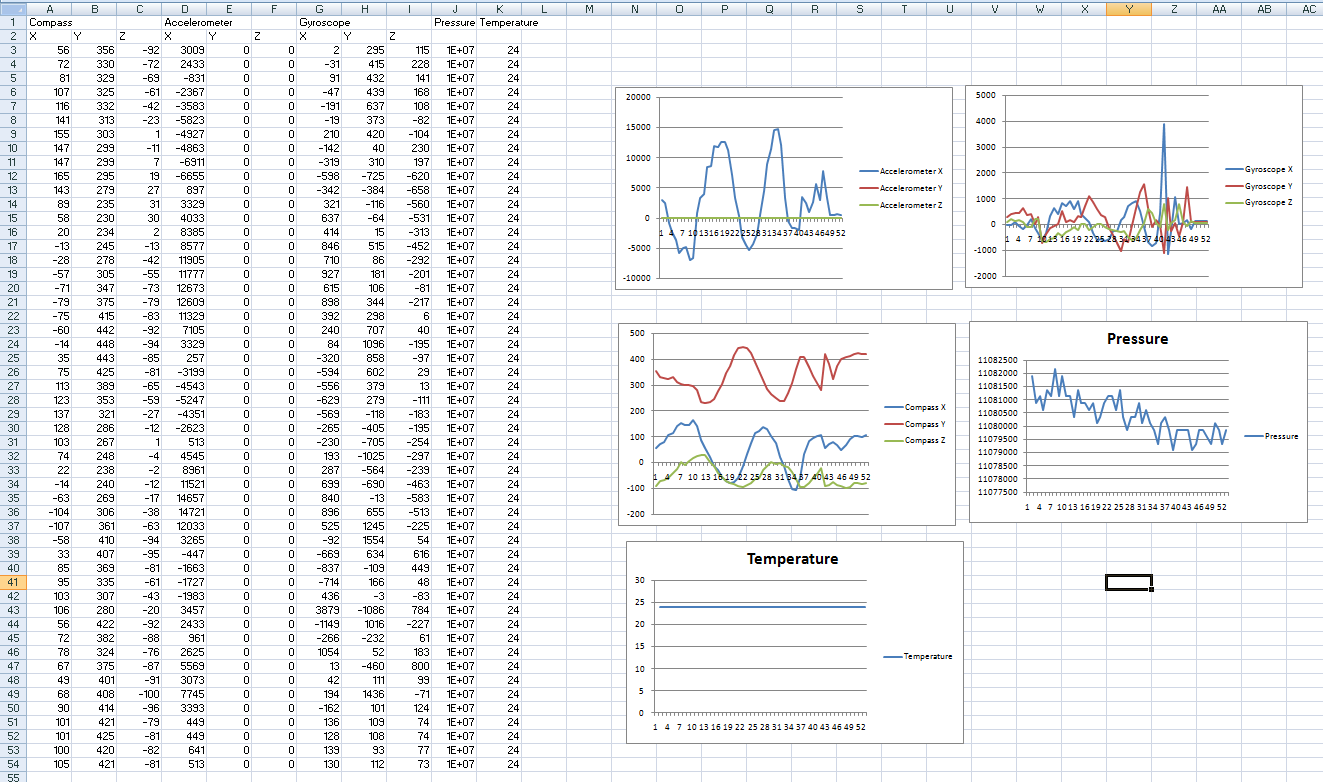

In a week or so, hopefully I’ll have enough of my old code transplanted to be able to stream the sensor data directly to a computer. Right now as a test, inserting a USB flash drive into the robot in place of the Bluetooth adapter will cause the sensor data to be logged to a text file. Importing that data into Excel gives pretty graphs:

Which is a neat trick, but impractical since it means the robot cannot be manually controlled. The final code should achieve something very similar, except in real time over a wireless serial link provided by the Bluetooth stack.

Once I’ve finished the code, written my thesis and presented the whole lot to the lecturer panel for grading, I’ll be building another four of these (on the University’s dime, of course!) for Latrobe to use for marketing purposes. Battlebots ahoy!